Effect of Shortage on Automotive Sector

Christiano Amon, the new CEO of global chipmaker Qualcomm recently said that the shortage might not end until late 2021. U.S automobile giant General Motors recently came out with concerns about a shortage of semiconductor chips that are used in their electric vehicles. Before this, global car manufacturers such as Audi, Mazda and Subaru had issued similar warnings about a shortage of chips and how it could severely affect production. In the U.K, Honda’s Swindon factory has been forced to halt production several times over the past few months because of this issue. The automotive industry had already been struggling with a larger production problem with factories being shut down at multiple places as part of Covid safety measures. Coupled with a lack of revenue, this compounded problem is expected to push automobile production to the backfoot.

General Motors stated that this chip shortage could translate to a global unit shortage of at least 216,000 vehicles, which is equal to about $2 billion in lost profits. Ford reported that the problem has led to a 20% decrease in production at their factories, which translates to a $2.5 billion decrease in revenue. While Stellantis has not officially disclosed any figures yet, it too called the shortage “a big unknown” that could majorly affect production. To make matters worse, several major electronics production facilities in Texas were closed down on account of the state’s harsh winter storm. This has massively affected the production of gaming consoles and other electronic goods too. Semiconductors form the core of most daily use electronics that have been in high demand during the lockdown. With production rates hitting all time lows, the deficit in the number of units has grown exponentially throughout 2020.

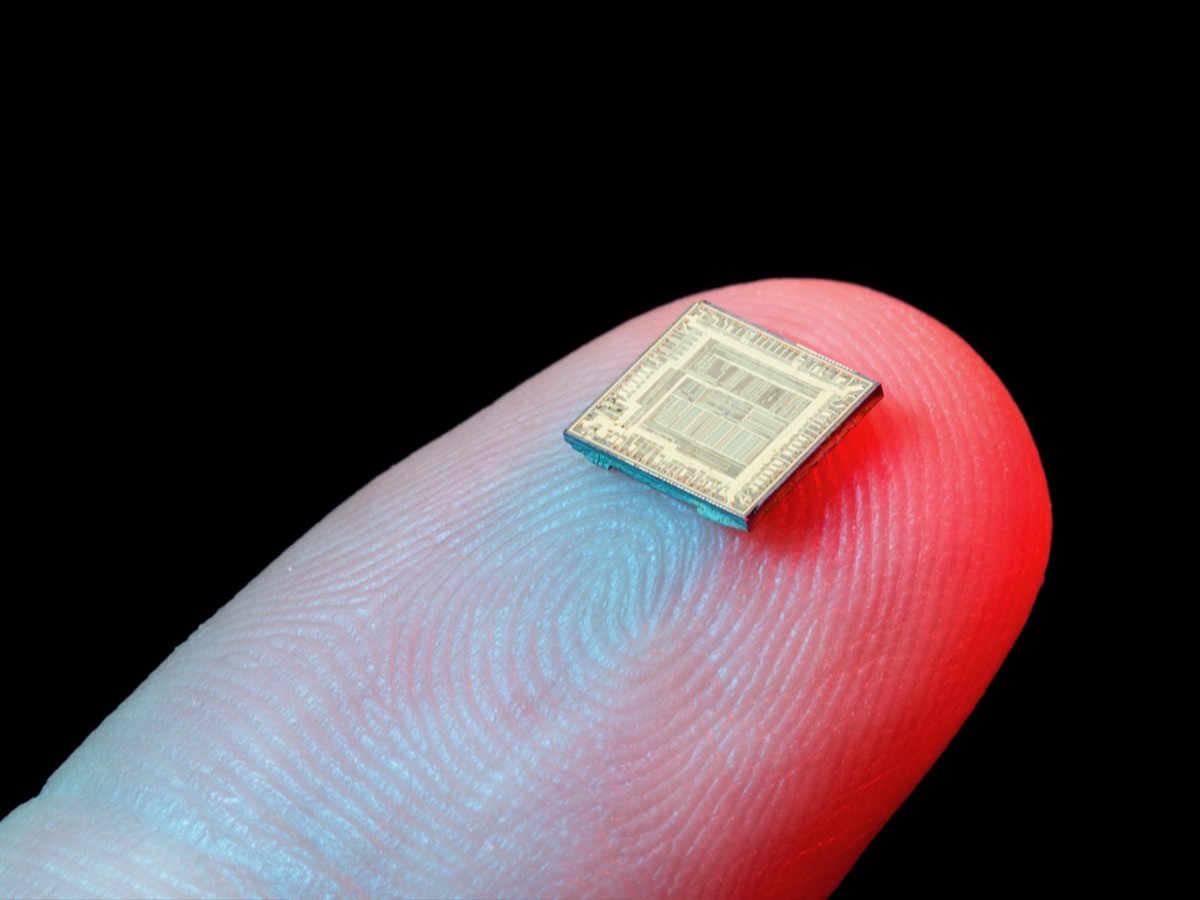

Simply put, the problem is : the coronavirus pandemic has massively affected the production of semiconductor chips. Major chips producing countries like China, Japan and India are coincidentally among the ones worst hit by the pandemic. This makes matters exponentially worse as it decapitates the major limbs in the production cycle. According to a Deloitte report, there are about 1,300 such chips in modern day petrol or diesel cars and about 3,500 in electric vehicles. About 50 to 100 of them have advanced functions, some of which are vital for the vehicle to function. This heavy dependency of vehicles on semiconductor chips makes it difficult for even non-electric vehicles to be produced in bulk in order to meet the rising demand. Cristiano Amon, Qualcomm’s incoming CEO. According to the director of the Semiconductor Industry Association, the demand for chips rose just as quickly in the autumn as it had fallen in the spring, causing a massive imbalance.

“If you asked me, ‘what keeps me up at night?’ right now [it] is this supply chain crisis we’re having in the semiconductor industry”

Forecast for the industry

The problem is expected to last for at least a year now, according to a comprehensive report published by Deloitte. While vaccines are certainly a sign of hope, the demand for these chips keeps on piling each day and the production is nowhere near normal as of now. By the time things return to normalcy, companies are expected to have a huge number of orders that would take anywhere between a few months to a year to fulfill. This means, automobile production could return to its normal volume as late as early 2022.

Recommended for you

Antidepressant Prescribing at Six-Year High

More people are taking antidepressants than ever. Is this a dark sign of the times or an indication that mental health stigma is changing?

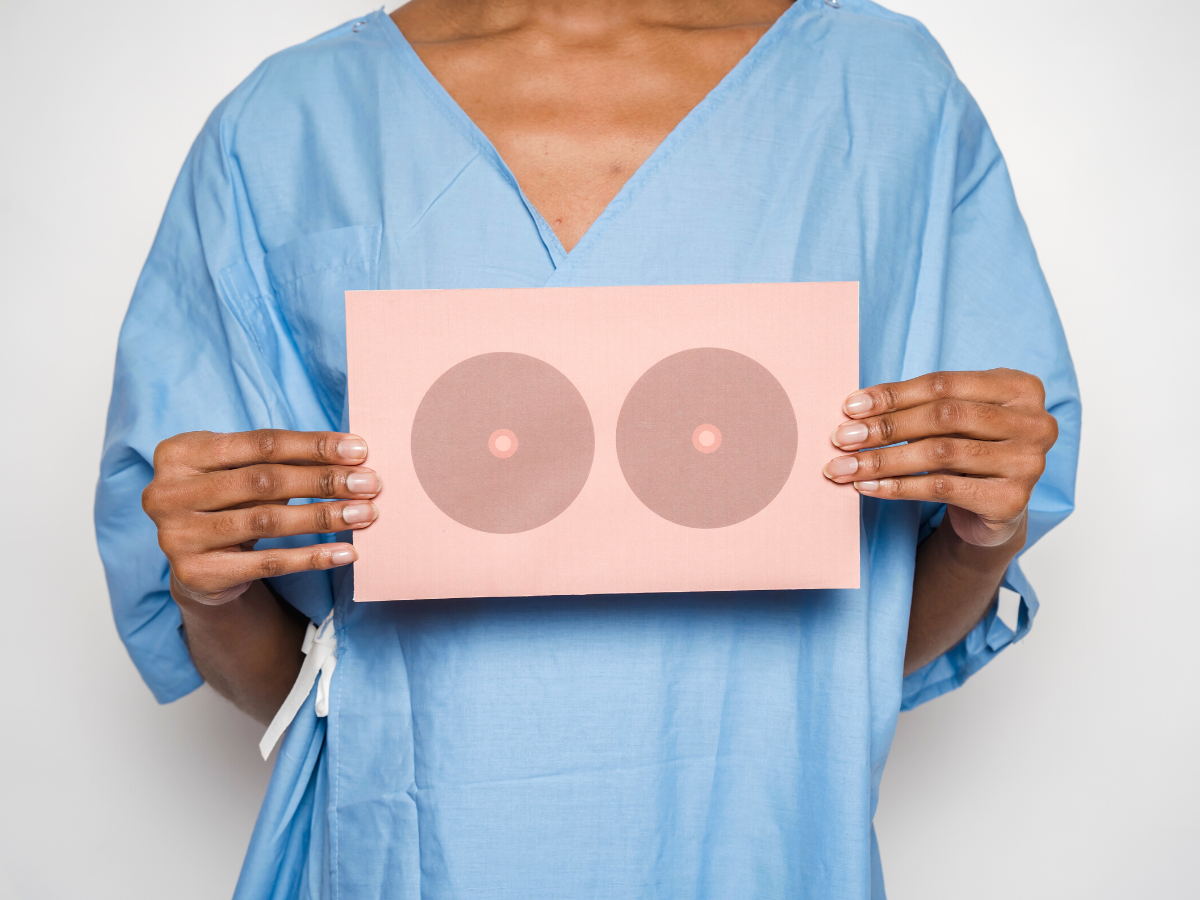

Can AI be Used to Determine Cancer Recurrence?

When cancer patients go into remission, they often worry about it coming back. AI can now help identify those at risk of cancer recurrence.

Pegasus – Still a Threat to the UK?

The notorious Pegasus spyware has been misused to exploit vulnerabilities in devices, even those kept within the walls of Number 10.

Trending

Drug Decriminalisation: Could the UK Follow Portugal?

Portugal’s drug decriminalisation has reduced drug deaths and made people feel safe seeking support. Would the UK ever follow suit?

Calling All Unvaccinated UK Adults

With Covid cases rising, the NHS is urging the 3 million UK adults who remain unvaccinated to come forward.